Printing Division 1947

The following photos appeared in the Westinghouse Newspaper in June 1947. It tells the story of the Printing Division once located in Trafford that made nameplate badges to identify Westinghouse products.

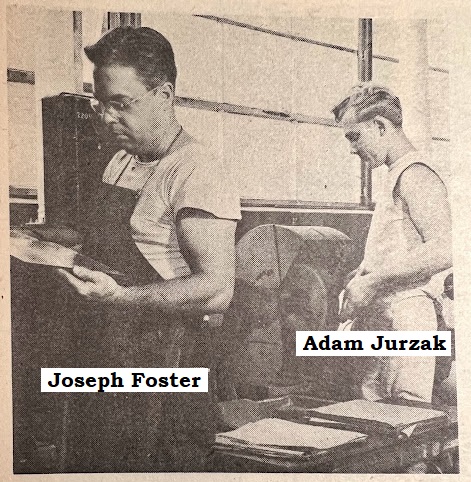

In 1947, there were nearly 12 million nameplates a year, ranging in size from three by two feet to ½ by ½ inch. The nameplates are made from sheet metal, smoothed, and buffed as Joseph Foster and Adam Jurzak are shown doing.

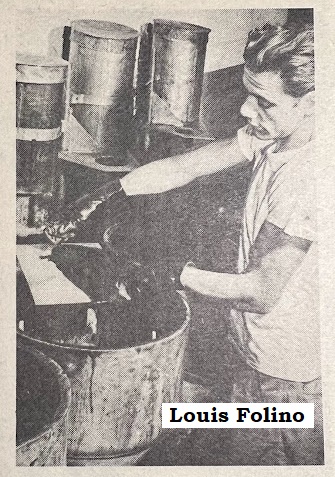

The sheets then get an electrolytic anti-corrosion finish. The prepared plate gets a coating of sensitizing material, after which Louis Folino whirls the plate at a great rate in a tube. Whirling spreads the film evenly on the plate's surface and throws off excess material. The plate is then ready to take an exposure.

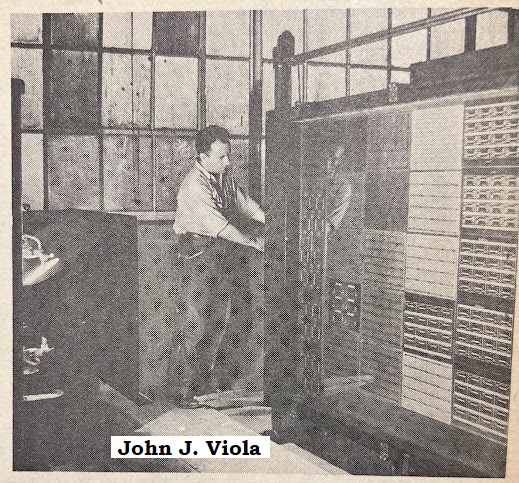

Exact drawings of the desired nameplate are photographed by an old-fashioned plate camera. The negatives must hold their dimensions exactly, so only those on glass plates are usable. The negatives are placed over the sensitized metal plates by John J. Viola, who exposes the plates to a 3,500-candlepower arc for a long interval. This prints the impression on the metal, just as an ordinary picture is printed in a darkroom on photographic paper.

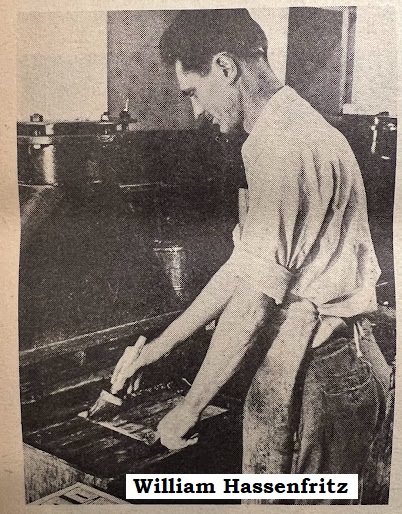

After the exposed plate is developed and fixed, it is given an acid treatment by William Hassenfritz. The acid eats into the exposed metal, leaving intact the parts that will appear against the background. The metal plate is cleaned and prepared for applying the color background.

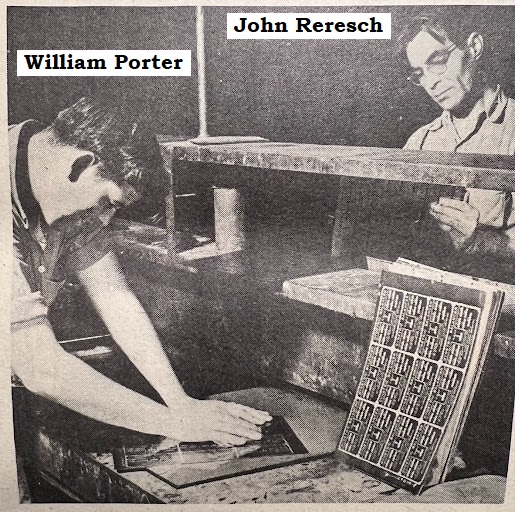

This metal sheet, which bears the imprint of half a dozen nameplates, has had a thorough coating of black paint. William Porter and John Reresch carefully rub off excess paint, leaving the lettering and the spaces for stamping data as "clean" metal. Nameplates are also made in combinations of two or more colors. Nameplates must be durable, legible and have a good finish.

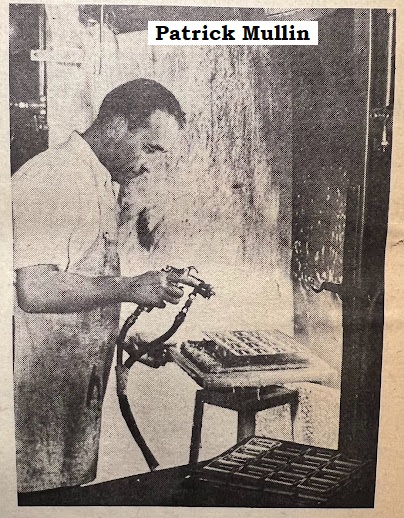

In this air-conditioned, water-curtain spray booth, Patrick Mullin is giving the finished plate a final coat of protective lacquer. The plate is now ready for a trip to a punch press, where it will be trimmed and given aligning holes to act as a guide for further work.

Jennie Nigra operates a punch press to cut the individual nameplates from the strips. The metal sheet is cut through, but the nameplates are carefully removed by hand. The Nameplate Division has over 700 punch press dies for punching out the differently shaped plates.

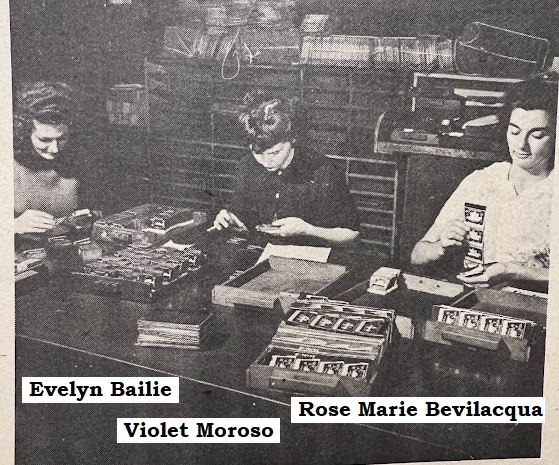

The last steps before the nameplates are shipped to the manufacturing division that ordered them to take place here. Evelyn Bailie, Violet Moroso, and Rose Marie Bevilacqua take care of removing the punched nameplates from the strip, inspecting them minutely for defects and sorting them. Nameplates previously were made at Baltimore, but the operation was shifted to Trafford last June.

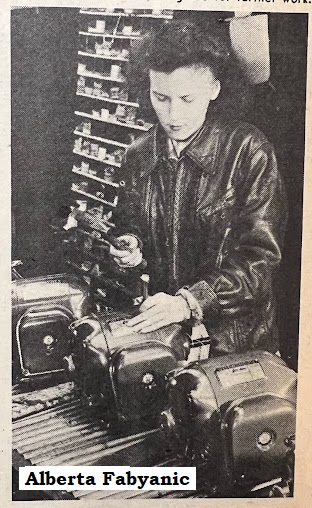

The pay-off for the efforts of the Trafford platemakers comes when the nameplate is affixed to Westinghouse products. Not only do the plates give apparatus the stamp of Westinghouse quality, but they also give users needed data. *UPDATE 9/7/2022 The Facebook post previously listed one worker as "unidentified" in the photo, but thanks to a family member seeing our post, she was identified as Alberta Fabyanic.